Within the realm of Heating, Ventilation, and Air Conditioning (HVAC) systems, Air Handling Units (AHUs) play a critical role in ensuring optimal air quality and temperature control within a building. But how are these workhorses efficiently managed and controlled? This in-depth exploration delves into the intricacies of AHU control systems, examining the components, strategies, and factors influencing their operation.

Understanding the Need for AHU Control

AHUs perform several crucial functions, including air filtration, temperature and humidity conditioning, and air delivery. To ensure these processes operate efficiently and meet the building’s specific needs, a sophisticated control system is essential. Here’s why AHU control is vital:

Maintaining Desired Conditions:

The control system constantly monitors temperature, humidity, and other parameters to ensure the conditioned air delivered by the AHU meets the occupants’ comfort requirements.

Optimizing Energy Efficiency:

By continuously adjusting operation based on real-time conditions, the control system helps minimize energy consumption by the AHU.

Ensuring Equipment Protection:

The control system incorporates safety features and alarms to prevent equipment damage due to overheating, excessive pressure, or other potential issues.

Adapting to Changing Demands:

Building occupancy and external conditions can fluctuate throughout the day or year. The control system allows the AHU to adapt its operation to meet these changing demands.

Essential Components of an AHU Control System

The core components of an AHU control system work in concert to manage its operation:

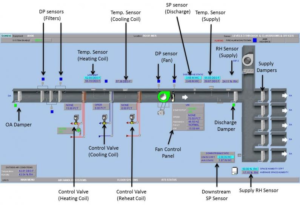

- Sensors: These devices monitor various parameters like temperature, humidity, pressure, and airflow within the AHU and the building itself. Common sensors include temperature sensors, humidity sensors, pressure switches, and airflow sensors.

- Controllers: These are the brains of the system, receiving data from the sensors and processing it based on programmed setpoints and control algorithms. Controllers can be programmable logic controllers (PLCs) or dedicated building automation system (BAS) controllers.

- Actuators: These devices translate the controller’s instructions into physical actions. Examples include variable speed drives (VSDs) for controlling fan speed, damper actuators for regulating airflow through different zones, and valves for controlling chilled or hot water flow to the coils.

- Human Machine Interface (HMI): This user interface allows facility personnel to monitor system operation, adjust setpoints, and troubleshoot potential issues. This can be a physical control panel on the AHU itself or a software interface accessible from a computer or mobile device.

Control Strategies for AHUs

AHU control systems employ various strategies to optimize operation:

- Setpoint Control: This basic strategy maintains a desired temperature or humidity level within the building by activating or deactivating components like heating or cooling elements based on sensor readings compared to setpoints.

- Demand Control Ventilation (DCV): This strategy adjusts the amount of ventilation air delivered based on real-time occupancy or CO2 levels. This can significantly reduce energy consumption without compromising indoor air quality.

- Scheduling: The control system can be programmed to automatically adjust setpoints or operating modes based on time of day or day of the week. For example, a lower temperature might be maintained during occupied hours and raised slightly during unoccupied periods.

- Cascading Control: In complex systems with multiple AHUs serving different zones, cascading contro

l allows for coordinated operation. A central controller might send setpoints or adjust operation based on feedback from individual zone controllers.

Factors Influencing AHU Control System Design

Several factors influence the design and complexity of an AHU control system:

- Building Size and Complexity: Larger and more complex buildings with multiple zones typically require more sophisticated control systems to manage varying needs.

- Ventilation Requirements: Buildings with specific ventilation requirements due to occupancy type or potential indoor air quality concerns might necessitate dedicated control strategies like DCV.

- Energy Efficiency Goals: Buildings with a focus on energy efficiency might utilize advanced control features like optimization algorithms and integration with building automation systems.

- Budgetary Constraints: The complexity of the control system can impact its cost. Striking a balance between functionality, efficiency, and budget is crucial.

Conclusion

AHU control systems play a vital role in ensuring optimal performance, occupant comfort, and energy efficiency within buildings. By understanding the core components, control strategies, and influencing factors, building owners and facility managers can make informed decisions when designing, selecting, and operating AHU control systems.

Looking to install a commercial HVAC System or Duct work in your Business Area?

Contact Vipul Ac to learn about our HVAC Service

Call +91 9825636606 Today.