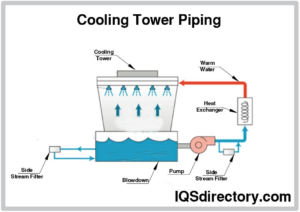

An open type cooling tower, also known as an open circuit cooling tower, is a heat rejection system that uses direct contact between warm water and air for cooling purposes. Here’s a breakdown of how it works:

- Structure: It’s an enclosed shell with some key components:

- Water distribution system: Sprays warm water over a large surface area.

- Fill material: Creates a labyrinth-like path for the water to trickle down, maximizing contact with air.

- Fans: Draw in outside air and circulate it through the tower.

- Cold water basin: Collects the cooled water at the bottom.

- Cooling Process:

- Warm water is pumped to the top of the tower and distributed by the water distribution system.

- As the water trickles down the fill material, it has a large surface area exposed to the air flow from the fans.

- Heat transfer occurs between the water and air.

- Additionally, a small amount of water evaporates due to the air contact. This evaporation absorbs heat, further cooling the remaining water.

- The cooled water is collected in the basin at the bottom and then recirculated for its intended use.

- The hot, moist air exits the top of the tower.

Cooling Tower Piping

Advantages of Open Type Cooling Towers:

- Simple design and construction

- Lower initial cost compared to closed-circuit cooling towers

- Very effective cooling, especially in dry climates

Disadvantages of Open Type Cooling Towers:

- Water usage and loss due to evaporation (makeup water required)

- Potential for mineral scaling and biological growth requiring maintenance

- Emissions of water vapor plume which can be visible and may cause concerns in some areas

Applications of Open Type Cooling Towers:

- Power plants

- Industrial processes

- HVAC systems for large buildings

- Refrigeration systems

Looking to install a commercial HVAC System or Duct work in your Business Area?

Contact Vipul Ac to learn about our HVAC Service

Call +91 9825636606 Today.