Which Compressor is used in cassette AC?

Cassette AC units typically use rotary compressors, specifically twin-rotary compressors. Here’s a breakdown:

-

Rotary compressors: These are a type of positive displacement compressor that uses a rotating vane to compress refrigerant vapor. They offer several advantages for cassette AC units:

- Quieter operation: Compared to reciprocating compressors, rotary compressors tend to be quieter, making them suitable for ceiling-mounted cassette units where noise reduction is desirable.

- Compact size: Rotary compressors are relatively compact, which is beneficial for fitting within the indoor unit of a cassette AC.

- Efficiency: Modern rotary compressors can be quite efficient, especially twin-rotary variants.

-

Twin-rotary compressors: An improvement on the standard rotary compressor, the twin-rotary design uses two intermeshing rotors to compress refrigerant. This design offers several benefits:

- Smoother operation: The twin-rotor design leads to smoother operation and reduced vibration compared to a single rotor compressor.

- Increased efficiency: Twin-rotary compressors can achieve higher efficiency levels compared to single rotary compressors, potentially leading to lower energy consumption for your cassette AC unit.

While rotary compressors are the dominant choice, there may be some exceptions:

- Cassette AC units with inverter technology might utilize a different compressor type optimized for variable-speed operation. It’s always best to consult the manufacturer’s specifications for the specific model you’re considering.

Overall, rotary compressors, particularly twin-rotary designs, are the standard choice for their quiet operation, compact size, and efficiency, making them well-suited for cassette AC units.

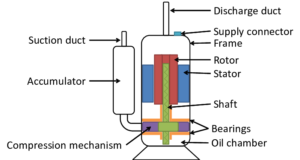

Rotary Compressor

Rotary compressors are known for their quiet operation and energy efficiency. They work by using a vane that spins inside a cylindrical chamber, compressing the refrigerant.